Batik Textiles

To create a new page, enter a unique page name below.

If a page with that name already exists, you will be sent to a form to edit that page.

For existing pages ... see category Batik Textiles.

Fill in the form with the details of your image and save the page.

Batik Textiles of Java

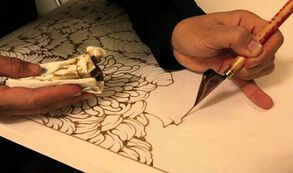

The Indonesian island of Java is the principal source of the brilliant textiles known as batiks. The terms batik derives from the Malay word meaning to draw with a broken dot or line and refers to the wax-resist process by which patterns are imposed on fabric. Many countries, especially in Asia, produce wax-resist textiles, but the Javanese have developed the most sophisticated method for executing the process. A liquefied wax compound is literally drawn on the surface of the cloth in order to keep either the pattern itself or the background areas from taking the dye. Each color thus requires separate application, leading to a multi-step production.

Although there are hints of earlier processes and textile types that perhaps led to batik, there is no evidence that the batik methods we know today are older than the early 19th century. The technique flourished in Java as a result of the introduction of fine imported cotton and the invention of the canting, an implement with a narrow tube fed from an attached reservoir for precise drawing with melted wax. Later in the 19th century, a further boost was given to production, though not to quality, with the development of the cap, a stamp for applying the wax resist much more expeditiously than drawing by hand. Some batik textiles combine both resist processes.

Traditionally, women have been the primary producers of batik. Dyeing, on the other hand, is a craft done by both men and women, though indigo-dyeing falls solely to men. The range of patterns, some identified by name, numbers well over a thousand. Javanese batik makers have always been open to a broad range of sources for their patterns and motifs: from local Javanese and Hindu works to Chinese, Arabic, and Western inspirations, including stories such as Cinderella and cartoons like Flash Gordon. Batik fabrics are mostly made into traditional garments such as sarongs (tubular skirts), skirt cloths, head scarves, shoulder cloths, and breast cloths. This display features a diverse selection of pattern and functional types, all from the museum’s rich collection, along with materials that further explain the batik process.

- The Step by Step Process of Making Batik

- Step 1 - The first wax is applied over the penciled-in outline of the pattern. Almost always the original cloth is white or beige.

- Step 2 - The cloth is dyed in the first dye bath. In this case the first dyebath is indigo blue. The area of the cloth where the wax was applied in Step 1 will remain white.

- Step 3 - Second application of wax is applied. In this case it is a dark brown color. A poorer quality of wax is used to cover larger areas of cloth. The darker color helps to differentiate it from the first wax applied. Any parts that are covered with this wax application will remain the indigo color.

- Step 4 - The cloth is dyed in the second dye bath. In this case it is a navy blue. Any areas that are not covered by wax will become dark blue.

- Step 5 - All the wax that has been applied thus far is removed. This is done by heating the wax and scraping it off and also by applying hot water and sponging off the remaining wax.

- Step 6 - Wax is applied to the area of the fabric that the artist wishes to remain the indigo blue color.

- Step 7 - Wax is applied to the area of the fabric that the artist wishes to remain white.

- Step 8 - The fabric is submerged in the final dye bath. In this case it is brown. Any areas of the cloth that have not been covered with wax will become brown.

- Step 9 - The finished cloth after all of the wax has been removed.

Cap or block printing

From the mid-19th century, batik production was increased by applying the wax with a metal stamp called a cap. The cap technique can usually be identified by the repetition of identical patterns, whereas in batik tulis, even repeated geometric motifs vary. Some batik combine the two techniques with batik tulis used for fine detail. It’s worth noting that batik cap is true batik; don’t confuse it with screen-printed cloth which completely bypasses the waxing process and is often passed off as batik.

More info:

Batik productionproces

Batik designs

Indonesian batik patterns and their philosophical meanings

Wikipedia: Parang batik

Parang batik motif

Indonesian batik patterns and the philosophical meanings

Video 1: Batik of Java